The Manufacturing Tech Australia podcast visited LEAP’s stand at this year’s Australian Manufacturing Week to interact with some of the new technologies that were on display. Here is a record of their conversation captured on their podcast with Paul O’Shaughnessy, PTC Business Manager at LEAP Australia (plus some photos and videos from our booth display with Monash Smart Manufacturing Hub and Monash Nova Rover!)

Archives

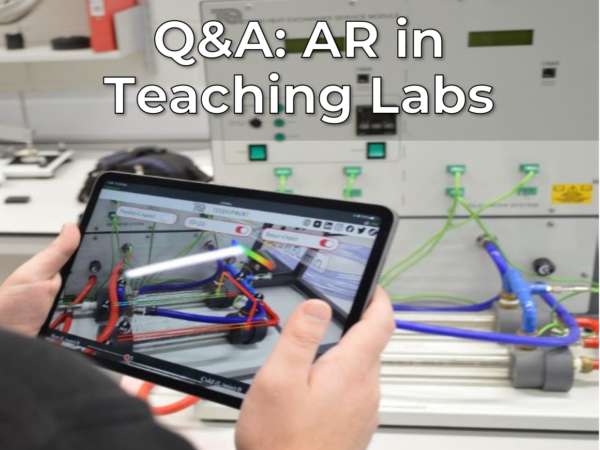

Q&A with Dr. Ben Simpson, NTU – Quantifying the benefits of Augmented Reality in engineering education

A conversation with Dr. Ben Simpson who is running a study to quantify the pedagogical benefits of incorporating AR into the engineering curriculum, starting with a range of year 1 teaching laboratories in mechanical engineering at NTU.

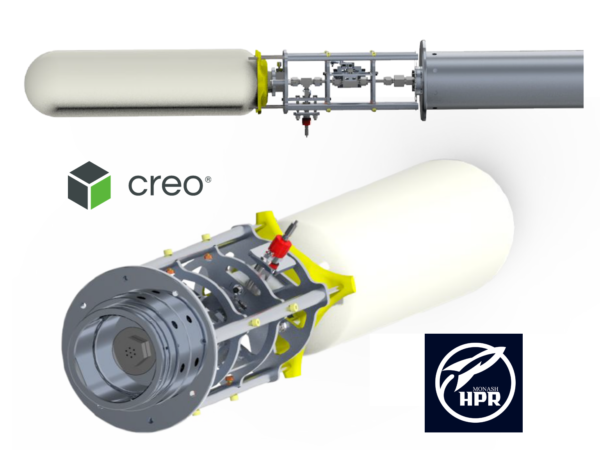

Guest Blog by Monash HPR: Design and construction of high-powered rockets with Creo and Windchill

Joe Zadnik from Monash High Powered Rocketry (HPR) explains how Creo & Windchill have been a pivotal part of the team’s recent product development phases and also discusses their recent success at the 2022 Spaceport America Cup.

Understanding Key Differences in PDM vs PLM

Product Data Management (PDM) and Product Lifecycle Management (PLM) are terms that are sometimes used interchangeably, but there are actually significant differences between them – in reality PDM is too narrow to describe the full breadth of capabilities that a true PLM system offers. LEAP’s recent webinar on this topic is summarised here to clear up any misconceptions about PDM and PLM for manufacturing organisations.

Easy Access to PLM information with ThingWorx Navigate

Improving Training, Maintenance & Instructions through Augmented Reality

Guest Blog: How RMIT University uses Augmented Reality & Digital Twin technology for NextGen aircraft sustainment

See how researchers at RMIT University are using emerging technologies such as Digital Twin and Augmented Reality (AR), created using Vuforia & ThingWorx, to support NexGen aircraft sustainment – with demonstrations on a full scale PC-9/A aircraft.

LEAP achieves PTC Advanced Partner Status for PLM and AR

Learn more about the PTC Advanced Partner Program (APP) which provides a key point of difference for PTC partners such as LEAP – demonstrating proven competence in particular technologies (such as PLM & AR).

Novel Uses of Augmented Reality (AR) in Aviation / Transport Safety education

Learn how the Australian Transport Safety Bureau (ATSB) & RMIT University used Augmented Reality to deliver a world-leading Transport Safety Investigation course for remote students during 2020, despite the challenges of COVID-19 disruptions.

Black Lab Design: How Onshape helped our shift to a fully integrated design and manufacturing facility

Learn how Black Lab switched from Solidworks to Onshape, driven by a need for greater flexibility with their CAD system and the challenges of documentation management and working with remote design teams – which have been uniquely satisfied by Onshape’s cloud-based solution.