About Black Lab Design: Based in Sydney, NSW, Black Lab Design has grown 120% in the past 12 months as it rapidly expanded from being a sheet metal fabricator to a complete design and manufacturing facility, with a team focused on design, manufacturing diversity, flexibility and super-competitive delivery times. “We are committed to working closely with customers from concept through to delivery and learning from the experience each time. I’m always happy to challenge the old ways of doing things if a better option exists,” explains Daen Simmat, CEO of Black Lab Design.

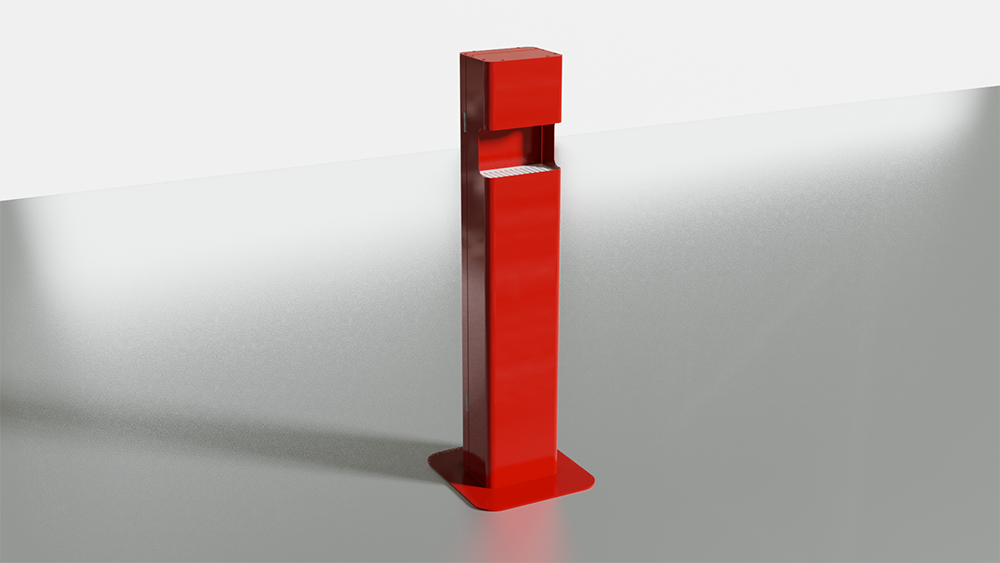

During this time, Black Lab Design has designed and produced many finished solutions, such as the hand sanitizer dispensers found in Australia’s largest supermarket chain, Woolworths.

Four years ago, Simmat and the Black Lab Design team switched from SOLIDWORKS to begin designing their parts in Onshape and have not looked back. At the time of switching, Simmat was driven by a desire for more flexibility with his software and the challenges of managing remote design teams (more recently accelerated by the COVID-19 pandemic), which have been uniquely satisfied by Onshape’s cloud-based solution.

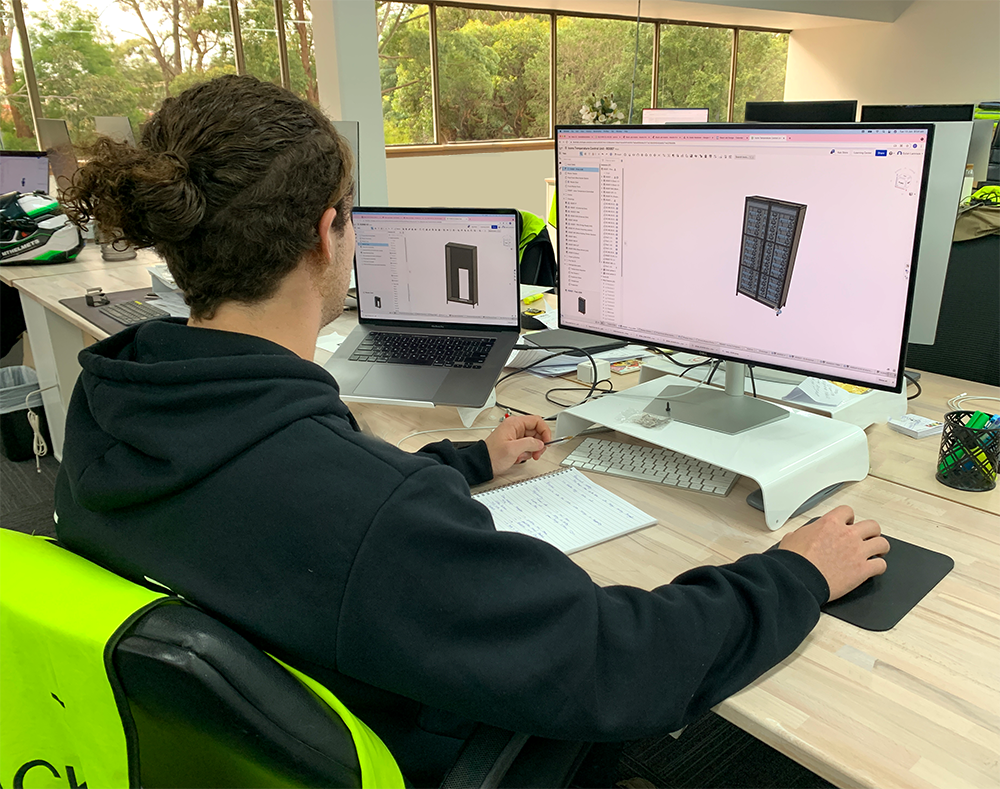

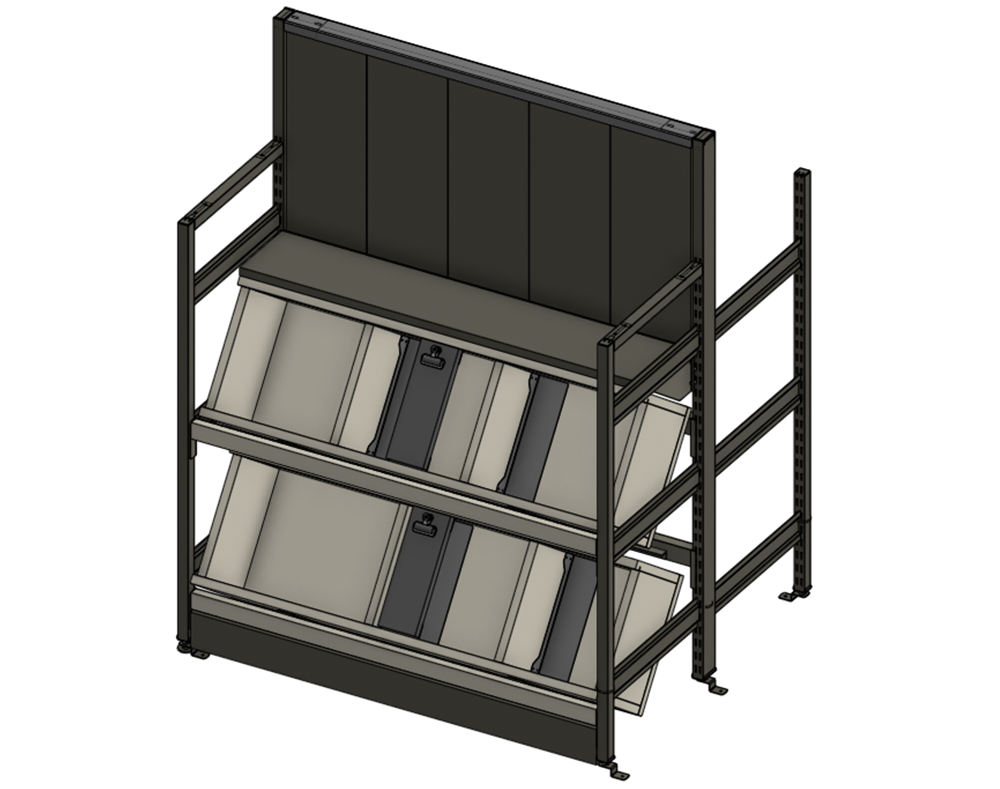

Onshape’s CAD software has been effective at improve the quality of designs as well as increasing the productivity of the design team through improved communications & documentation management – with ‘one version of the truth’ stored for each design, including cost estimates based on material type, finish and thickness, alongside the actual CAD geometry. “We’ve got a design team based across Melbourne and Sydney, and we needed the right infrastructure to support that sort of remote working using modern collaborative design tools. Also, we sought flexibility to have staff using their preferred devices, such as Macbooks,” Simmat explains.

The Black Lab Design Hygiene Station XL. (Image courtesy of Black Lab Design.)

Four years ago, Simmat and the Black Lab Design team switched from SOLIDWORKS to begin designing their parts in Onshape and have not looked back. At the time of switching, Simmat was driven by a desire for more flexibility with his software and the challenges of managing remote design teams (more recently accelerated by the COVID-19 pandemic), which have been uniquely satisfied by Onshape’s cloud-based solution.

Onshape’s CAD software has been effective at improve the quality of designs as well as increasing the productivity of the design team through improved communications & documentation management – with ‘one version of the truth’ stored for each design, including cost estimates based on material type, finish and thickness, alongside the actual CAD geometry. “We’ve got a design team based across Melbourne and Sydney, and we needed the right infrastructure to support that sort of remote working using modern collaborative design tools. Also, we sought flexibility to have staff using their preferred devices, such as Macbooks,” Simmat explains.

Images courtesy of Black Lab Design

Indeed, with Onshape hosted in the cloud and accessed through any web browser, Black Lab designers can work from anywhere and from any device (even tablets or smartphones, as circumstances dictate). “One happy side effect is that our hardware expenses have gone from $5,000 per computer down to less than a thousand dollars” Simmat notes. “From an IT logistics and data management perspective, Onshape is just so simple – I’d never consider returning to a system that required me to think about IT staff maintaining file servers, managing ongoing backups and the fear that at any point we might lose our data.”

With a different licencing model compared to his previous use of networked/floating licences, Simmat weighs up the need for Onshape licences for each named user and judges the overall cost of Onshape to be favourable to Black Lab’s bottom line. Plus, he notes that Onshape provides additional savings by removing all the ancillary costs associated with PDM. “If I compare the cost of SOLIDWORKS to Onshape and the document management component of Onshape, there’s definitely been a benefit with Onshape financially,” Simmat said.

Simmat also explained in a recent blog how he views product development as a team effort, not only internally but also externally with your client and the clients’ end customers. Thus, it is important to him that CAD designs are easy to share among all team members who are working on the same product. With Onshape, sharing is instantaneous and it’s unique collaborative tools provide instant feedback amongst all stakeholders: whether they are next door, in another suburb or another city.

“We have been extremely proactive in seeking business with some of Australia’s largest companies and I believe a big part of this recent success is based on having the right systems in place to deliver on what we promise.” Simmat reflects. “We are proud of this and we’re happy to share details of how we’ve achieved this publicly, even to our competitors. I’m a strong believer that having more efficient manufacturers overall will help make Australia a better place for successful local manufacturing.“

Get in touch with Daen and the Black Lab Design team via their website here.

Learn more about how Black Lab uses Onshape in this recent blog and also speak with LEAP about the unique advantages of Onshape for your business via LEAP’s main Onshape page.