Dr. Ben Simpson is the Deputy Head of Engineering at Nottingham Trent University in the UK. Ben has a passion for creating authentic and flexible learning environments to facilitate student learning through a ‘learning by doing’ philosophy. Across his career, Ben has worked as a consultant engineer, an industry team leader, a commercialisation manager and a senior academic in the UK and Australia.

What excites you the most about Augmented Reality (AR) and what motivated this investigation?

I’ve seen so many good examples of AR being used in the retail, entertainment and more generally in the engineering industry, such as visualising complex assemblies, facilitating training programmes, and developing maintenance programmes and manufacturing lines. However, to my knowledge, AR technology has not been widely adopted for educational purposes by university engineering departments, despite its clear potential benefits (in my mind, at least!).

Our study aims to quantify the educational benefit of integrating AR into an engineering curriculum – using new content developed to aid the teaching of existing engineering laboratories at NTU.

The examples we’ve worked on so far incorporate FEA/CFD simulation results into 3 laboratory experiments:

- Bending beam (visualisation of stress, strain and bending moment distributions);

- Flow over an aerofoil at various angles of attack (visualising the post-stall regime); and

- Concentric tube heat exchanger (visualisation of the flow and temperature distributions)

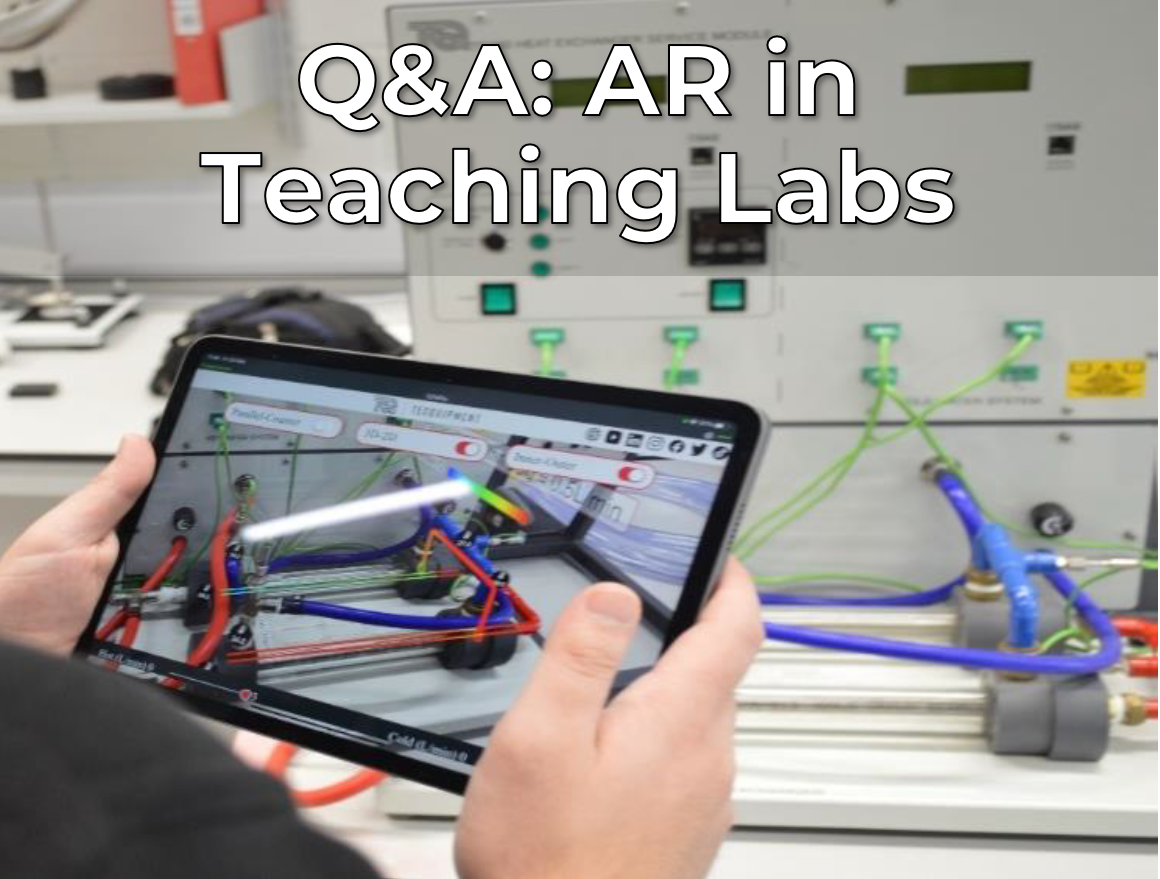

Figure 1: Laboratory experiments incorporated into AR study

In what ways do you anticipate AR will help when teaching engineering?

The early feedback we’ve received from students so far seems to suggest, that an interactive AR tool which visually enhances the overall laboratory experience, could play a key scaffolding role to help a student understand complex physics.

More generally, I see AR will play a useful role in:

- Improving engagement in laboratories, and as a natural ‘conversation starter’;

- Overcoming language/communication barriers for complex theoretical concepts, especially for students who identify as visual learners;

- Encouraging long-term memory retention of core engineering concepts which help develop a student’s “engineering intuition”.

What makes your study unique?

Previous studies have mostly focused on a single ‘standalone’ experience, and they only report the results of experience surveys completed by the participants immediately after the lesson without any longer-term follow ups to gauge knowledge retention. We’ve seen that the results reported are almost always positive, but we want to separate the student’s increased levels of engagement from the ‘WOW’ factor (which we expect) from an improvement in understanding and knowledge retention. Additionally, we aim to assess whether AR experiences can naturally fit with other educational delivery methods (lecturing, laboratories, discussion groups etc.).

Our study is focused on AR experiences that have been embedded in the standard engineering curriculum (i.e., they will be used regularly in the year 1 teaching laboratories for mechanical engineering). The quizzes are developed to assess the benefits of incorporating AR technology from a pedagogical point of view.

How are the student surveys being conducted?

Students are first asked to fill out a preliminary survey to gathers demographic information.

Students are broken into a control group (who conduct the laboratory without access to the AR) and a test group who actively use the AR experience within the laboratory.

Immediately after the laboratory, students are required to do a:

- Physics quiz – testing the student’s understanding of the physics involved in the laboratory.

- AR experience survey (only taken by the test group).

A follow-up quiz is also conducted three months later to assess the student’s memory retention of the topics studied in each laboratory.

Figure 2: Examples of AR experiences on laboratory equipment

What hardware is being used for the AR?

iPad Pros are the preferred option to deliver the AR experiences for our study. The experiences were also developed for the Microsoft Hololens using Vuforia Studio, but in these cases the more immersive experience afforded by the Hololens did not seem to add to the experience for the learner.

Is commercial software required to view and create the experiences?

The AR experiences can be viewed in a free app called Vuforia View; however, a license of Vuforia Studio was required to develop & host the experiences in the cloud.

The content for each experience was created in commercial software (ANSYS simulations and Vuforia Studio for AR authoring/hosting) because we wanted the experiences to be at the highest quality (both in terms of accuracy of simulated results and the AR user experience).

Do you have any plans for further study with AR after this trial is finished?

Yes, we plan to create more experiences and implement these into our engineering curriculum at NTU – particularly with a focus on complex engineering concepts found in fluid mechanics and solid mechanics. The longer-term goal is to introduce personalised learning paths – where students can learn at their own rate and the role of the tutor moves from one of teaching to guiding.

Further details of the project scope can be found in the paper submitted to the 22rd Annual Conference of the Australasian Association for Engineering Educations (AAEE 2022) and presented earlier this week (Dec 5th):

For any questions about this study or if you’re interested in further collaboration on this topic, please contact Dr Ben Simpson at ben.simpson@ntu.ac.uk

This research was funded by Innovate UK and TecQuipment, engineering education grant number 12276. Knowledge Transfer Partnerships (KTPs) aim to help businesses improve their competitiveness and productivity through the better use of knowledge, technology, and skills within the UK knowledge base. The authors would also like to thank LEAP Australia for their technical support during this project.