Creo 10 Highlights

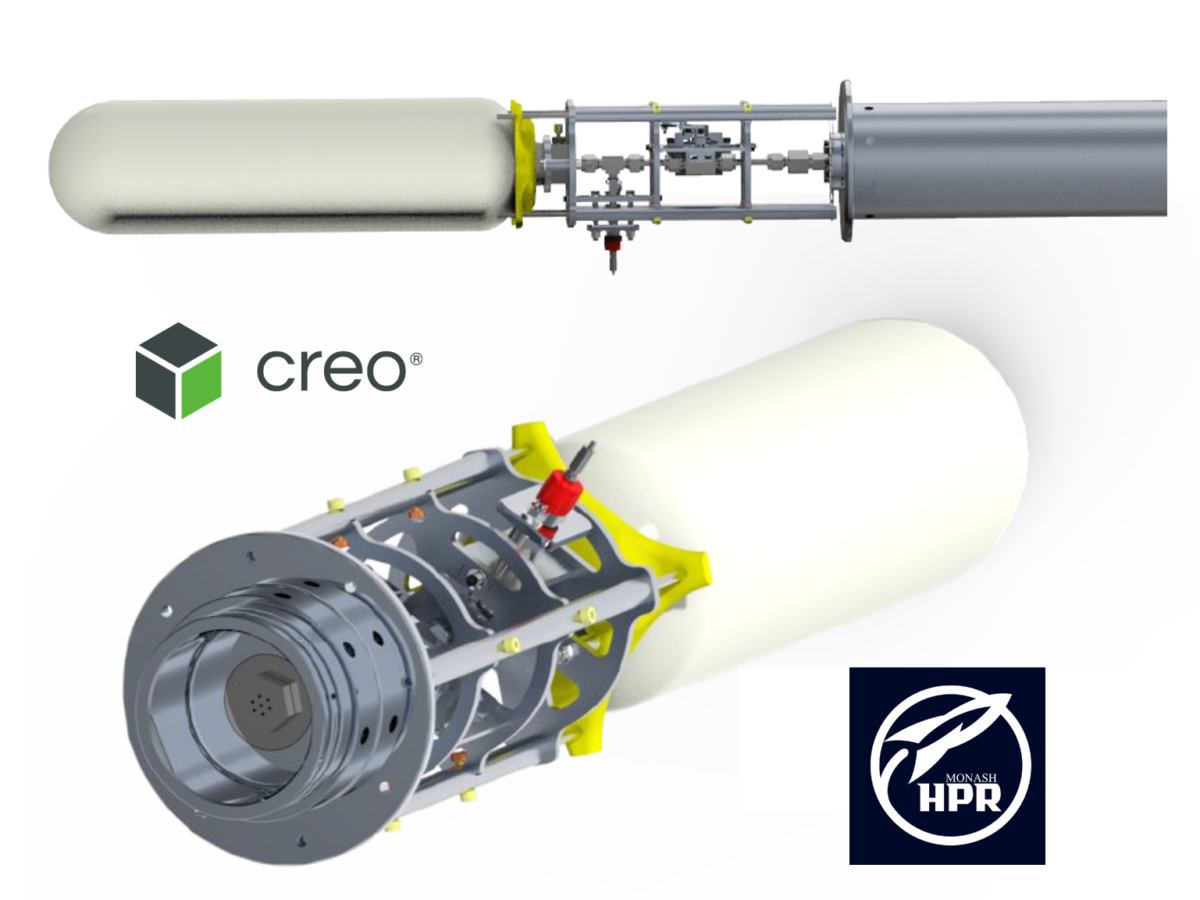

Joe Zadnik from Monash High Powered Rocketry (HPR) explains how Creo & Windchill have been a pivotal part of the team’s recent product development phases and also discusses their recent success at the 2022 Spaceport America Cup.

See how PTC Windchill RV&S is used to manage the requirements of multi-disciplinary systems with a modern web interface and client application designed for multiuser collaboration and end-to-end traceability.

Highlights from LEAP’s recent webinar on Windchill’s Risk & Reliability suite – the industry strandard software for analysing product performance, reliability, and safety data as well as maintaining best practices within a collaborative industry environment.

Product Data Management (PDM) and Product Lifecycle Management (PLM) are terms that are sometimes used interchangeably, but there are actually significant differences between them – in reality PDM is too narrow to describe the full breadth of capabilities that a true PLM system offers. LEAP’s recent webinar on this topic is summarised here to clear up any misconceptions about PDM and PLM for manufacturing organisations.

Part 2 – How can Creo users increase the value of their CAD models by using more advanced functionality – recordings are here on-demand and cover the use of Augmented Reality for design reviews, creation of high-quality technical illustrations and service documentation, plus generating engaging customer marketing collateral directly from your CAD model.

Learn more about the PTC Advanced Partner Program (APP) which provides a key point of difference for PTC partners such as LEAP – demonstrating proven competence in particular technologies (such as PLM & AR).

In the final installment of our 6-part Windchill PLM webinar series, we discuss how Windchill’s core content management capabilities and the ability of organisations to utilise them as a ‘single source of truth’ facilitates collaboration across departments outside of engineering and beyond.