Throughout the product development process how much time would you estimate is wasted by design teams searching for existing parts? And when one can’t be found, how often is a duplicate part created, and at what cost? Chances are, too much engineering time is being spent on these non-value adding tasks.

With parts classification, you can get the majority of that time back!

LEAP’s PTC Technical Manager, Allan Thompson recently presented a webinar entitled Reduce Costs by Improving Parts Re-use with Windchill Parts Classification which explained how, by reducing the number of duplicate parts and drawings, manufacturing and service engineers can more easily plan, assemble, test and execute – reducing costs and increasing efficiency across the enterprise. Read on and watch clips of the presentation below to learn more.

In the first clip below, Allan provides an overview of Windchill PLM – an enterprise system for your product data built upon the three pillars of:

- Digital Product Definition: Management of all of the digital content that is created in the product design process.

- Strategic Processes: How the digital content and associated data is managed as it moves through different areas of the organisation.

- Visualisation: How the product data is then viewed by different areas of the organisation.

Allan then goes on to explain Windchill’s object-based digital data model and how all information pertaining to a product structure, its associated CAD data, assemblies, derived content, version histories and so on can be managed using Windchill.

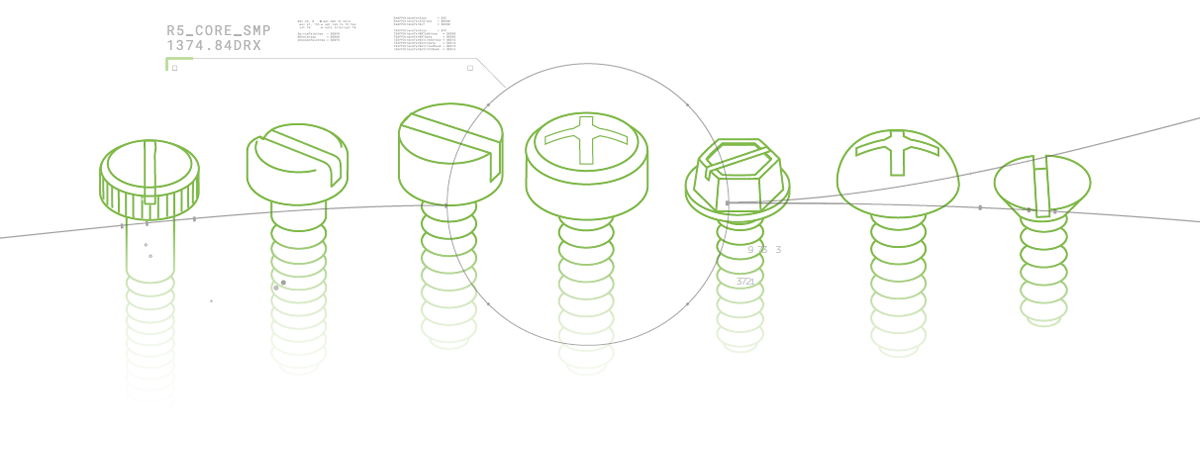

In the following clip, Allan discusses the concept of classification and why it is particularly important in aiding efficiency, especially when talking about engineering. Many challenges faced by product designers can be alleviated by adopting parts classification into the data management process, such as:

- Inability to find / reuse parts (leads to proliferation and duplication),

- Designers recreate models leading to lower productivity,

- More parts in inventory increases costs.

Allan then goes on to look at Windchill Partslink which allows users to define classifications for their parts and documents and establish a heirarchy to facilitate better organisation of their product data. Users can then leverage this classification for improved search and reuse of parts and even build and browse a catalog of parts. Watch the video below to learn more.

Finally Allan provides a live demonstration of Windchill Partslink in action, taking you through the process of searching for specific parts within Windchill, including searching for parts with particular facets or even searching for parts with similar characteristics to another. He then walks through the process of how to set up classifications within Windchill, defining a part and its facets in real-time.

We hope you found this presentation informative. If you would like any further information about Windchill or Partslink please contact LEAP and one of our experts will be in touch to discuss your needs.