Every seat of Creo now includes multibody design capabilities which can dramatically simplify part design. These capabilities can greatly improve modelling efficiency when you wish to:

• Design interdependencies between two parts.

• Split a solid part into multiple parts.

• Use multiple materials in a single part.

Taju Joseph, Application Engineer at LEAP Australia recently presented a webinar looking at the surprising ways Multibody Design can help you develop higher quality products faster. Below we have summarised this webinar and included clips of the presentation. Read on to learn how you can start working smarter with Creo Multibody Design today.

In this first clip, Taju explains how working with multiple bodies – independent geometric volumes within the part design environment which can be separately managed and visualised – allows for more flexible, efficient and advanced workflows within Creo.

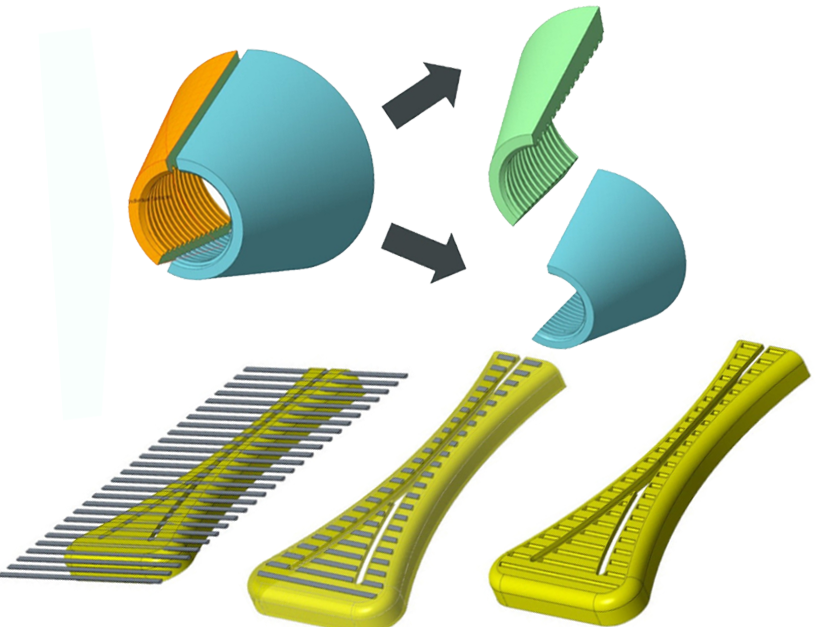

Taju then goes on to explain how bodies can be used as “design tools” to simplify and manage geometry creation. For example Boolean Operations can be used to merge, subtract or intersect multiple bodies, or you can split or mirror bodies by leveraging body operations. This is followed by a live demonstration of these features which illustrates the power of this functionality.

In the following clip Taju provides an overview of some of the additional areas that the Multibody Design approach can be used, including:

- Flexible modelling

- Additive Manufacturing

- Simulation

- Generative Design

Taju then gives another live demonstration of Creo, showing how the Multibody approach can be applied to each of the applications listed above.

Taju then looks at examples of other Creo applications that can benefit from the Multibody approach, including:

- Sheetmetal design

- Multi-material parts

- Creo Unite Technology

Taju’s live Creo demonstration in the video below showcases the benefits of adopting the Multibody Design approach – enabling advanced design workflows and multi-material parts, reducing reference complexity and increasing usability and productivity.

We hope that you found this article informative and that you are now confident to try using the Multibody Design approach yourself. As always, if you have any questions or would like assistance with Creo please contact the team at LEAP.