Highlights from LEAP’s recent webinar on Windchill’s Risk & Reliability suite – the industry strandard software for analysing product performance, reliability, and safety data as well as maintaining best practices within a collaborative industry environment.

Archives

Understanding Key Differences in PDM vs PLM

Product Data Management (PDM) and Product Lifecycle Management (PLM) are terms that are sometimes used interchangeably, but there are actually significant differences between them – in reality PDM is too narrow to describe the full breadth of capabilities that a true PLM system offers. LEAP’s recent webinar on this topic is summarised here to clear up any misconceptions about PDM and PLM for manufacturing organisations.

Easy Access to PLM information with ThingWorx Navigate

Getting the most out of Creo (Part 2)

Part 2 – How can Creo users increase the value of their CAD models by using more advanced functionality – recordings are here on-demand and cover the use of Augmented Reality for design reviews, creation of high-quality technical illustrations and service documentation, plus generating engaging customer marketing collateral directly from your CAD model.

Cloud-based Solutions to the challenges of Product Data Management

Reduce Costs by Improving Parts Re-use with Windchill Parts Classification

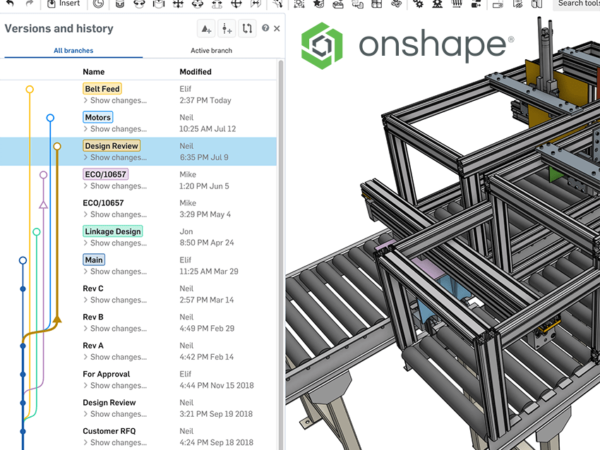

Why has Onshape become the #1 Fastest-Growing CAD Software in the World?

According to engineering.com, Onshape is now the fastest-growing CAD system in the world, with users topping 2 million and a rapid growth rate of 7x the average of other CAD systems. At the end of a challenging year, we reflect on the factors that have led to this rapid uptake of Onshape across Australia, New Zealand & the world!

Advanced Assembly Design with Creo

Any time a team works with complex assemblies, they risk miscommunications, gaps, and overlap. The result? Errors and rework. That’s why Creo develops powerful capabilities for managing all of your most complex assemblies. Recently Taju Joseph, Application Engineer at LEAP Australia presented a webinar looking at the advanced assembly design capabilities within Creo and how they can help improve the quality of your models. This post provides a summary and includes video clips of the live demonstrations presented in this webinar.

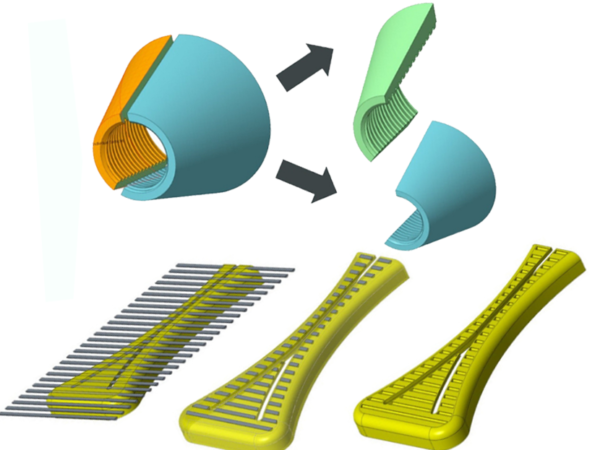

Creo Multibody Design

Every seat of Creo now includes multibody design capabilities which can dramatically simplify part design and improve modelling efficiency. We recently presented a webinar looking at the surprising ways Multibody Design can help you develop higher quality products faster which we have summarised in this article including video clips of the presentation. Read on to learn how you can start working smarter with Creo Multibody Design today.

Kickstarting Factory IoT with ThingWorx Applications

Pressure on manufacturers to maximise production performance has never been higher, yet many companies still face significant challenges in acquiring, managing, sharing and acting upon the production data that will help them to achieve their goals. The adoption of the ThingWorx IoT platform and in particular implementing Thingworx Applications for use cases such as real-time asset monitoring, allows manufacturers to quickly resolve these production data management issues, lowering operating costs and increasing asset efficiency.